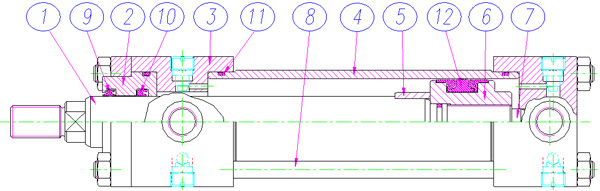

Tie Rod Cylinder

Technical Features

- Piston Rod – Standard C45/C50 medium carbon steel, hard chromium plated at least 20 µm thickness. Max. surface roughness, Ra ≤ 0.2 µm (8 Rms); diameter tolerance ISO f7. Yield stress is 340 to 517 N/mm2.

- Gland Cartridge- Machined from ductile iron for maximum bearing support and wear resistance.

- Steel Head And Cap– Bored and grooved to provide concentricity for mating part.

- Cylinder Barrel- Heavy wall steel tubing honed or skived and roller burnished to micro finish bore to assure minimum seal friction and wear.

- Head End Cushion (optional)– Precision machined design.

- Piston – Designed to assure leak proof and reduced bearing load. Material of ductile iron or steel.

- Cap End Cushion (optional) – Precision machined to assure effective cushion effect. It is an integrate part of the piston rod.

- Tie Rod– Tie rods are make form high tensile steel of minimum yield strength of 700 N/mm2 (100000 psi).

- Rod Wiper – Double-lip rod wiper provides dirt protection and wipes rod clean on in-stroke.

- Rod Seal - Polyurethane rod seal assures positive sealing and minimise frictional drag.

- End Seals - O-ring provides positive sealing between head & barrel.

- Piston Seal - High pressure piston seal with Teflon wear ring provides leak proof operation.